Zinc whiskers are a hidden yet serious contamination risk commonly found in raised floors, equipment racks, and zinc-coated metal surfaces. Laboratories and cleanroom environments are particularly vulnerable, as even the smallest particulate can compromise results, safety, and compliance. This article explains what zinc whiskers are, why they form, and how proper laboratory cleaning prevents costly operational and contamination risks.

What Are Zinc Whiskers?

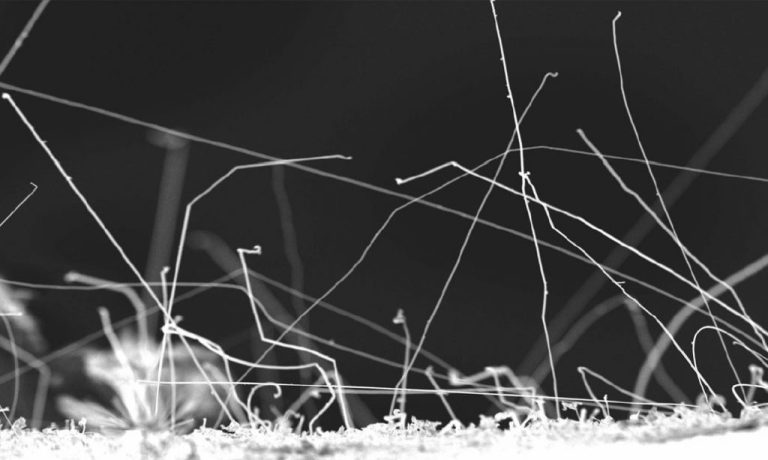

Zinc whiskers are microscopic, conductive, hair-like metallic filaments that grow spontaneously from electroplated zinc surfaces. They can easily detach due to vibration, airflow, or the natural ageing of infrastructure. Although invisible to the naked eye, these filaments are capable of causing major system disruptions or contamination in sensitive environments.

Common sources include raised floor tiles, metal cable trays, server racks, access flooring, and other ageing metallic components coated with zinc. Once dislodged, zinc whiskers can circulate through the air and settle on delicate instruments or electronic systems.

Why Zinc Whiskers Are a Threat in Labs

In laboratories, zinc whiskers can interfere with high-precision instruments such as microscopes, diagnostic devices, analytical equipment, and electrical systems. These contaminants can lead to:

- Data errors or inaccurate readings.

- Airborne contamination that compromises cleanroom standards.

- Short circuits or electronic malfunctions in sensitive instruments.

- Corrosion or surface damage to precision components.

In pharmaceutical, biotech, semiconductor, or medical laboratories, such contamination can jeopardise research validity, compromise sterility, and affect product integrity. In clinical settings, inhalation or ingestion of fine metal particles may even pose minor but notable health risks.

How Zinc Whiskers Spread

Once dislodged, zinc whiskers spread easily through environmental factors such as airflow from HVAC systems, equipment vibration, and foot traffic. These filaments accumulate in:

- Air filters

- Ventilation ducts

- Instrument interiors

- Work surfaces

Because of their microscopic size, zinc whiskers are difficult to detect without specialised inspection tools such as high-magnification microscopes or surface particle testing devices.

The Role of Proper Laboratory Cleaning

Specialised Contamination Removal

Standard janitorial cleaning often spreads zinc whiskers instead of removing them. Laboratories require HEPA-filtered vacuums, anti-static tools, and controlled procedures to safely capture and remove these conductive particles without reintroducing them into the air.

Inspection and Testing

Professional services include particle count testing, surface sampling, and microscopic analysis to confirm the presence and severity of zinc whisker contamination. These inspections help laboratories identify affected areas before contamination leads to costly downtime or equipment failure.

Containment and Prevention

Proper cleaning prevents cross-contamination between rooms, equipment, and controlled zones. Facilities may require air scrubbing, filter replacement, or cleanroom-grade air purifiers to maintain safe air quality and containment integrity.

Long-Term Mitigation

Long-term control involves replacing zinc-coated materials with alternatives such as powder-coated steel or stainless steel. Establishing routine inspection and cleaning schedules ensures that regrowth or build-up is identified and addressed early, maintaining a contamination-free laboratory environment.

Signs Your Lab May Have a Zinc Whisker Problem

Watch for these early warning signs:

- Unexplained electrical failures or static-related system errors.

- Recurring contamination spikes were detected during particle testing.

- Small metallic fragments were discovered during equipment maintenance.

- Corrosion or visible ageing on raised floors or metal racks.

If one or more of these indicators appear, it’s crucial to schedule a professional inspection immediately to prevent further contamination or operational risks.

Keep Your Laboratory Clean, Safe, and Compliant

Zinc whisker contamination may be invisible, but its effects on laboratory performance, safety, and compliance can be significant. Regular laboratory cleaning, targeted inspections, and proactive material maintenance are essential to maintaining a contamination-free environment.

Schedule a zinc whisker inspection or cleaning assessment with Data Clean Asia today to ensure your laboratory remains compliant, safe, and fully protected against hidden contamination threats.